Managing obsolescence, spare parts, and refurbishments ensure peak performance. Next generation planning capitalizes on innovation

MANAGE OBSOLESCENCE

The component parts within an automated manufacturing system are subject to independent lifecycle management by the vendor. The earlier an obsolescence risk can be identified, the more time is available to develop a range of mitigation strategies ensuring equipment availability is maintained.

Benefits

- Maintain updated BOM and drawings

- Reduce risk of stockouts due to obsolete parts

Scope

- Preliminary Assessment – Analysis and summary of initial insights on obsolescence breakdown, including lifecycle and critical vs. non-critical component risk

- Full Assessment – Detailed review of the entire system BOM to provide early warning of potential obsolescence risk

- BOM Management – ATS will monitor asset BOM and notify customers of any parts that have become obsolete

- With Full BOM Management ATS will dedicate a specified amount of time to validate direct replacement, perform indirect replacement studies, and update drawings and BOMs as applicable

SPARE PARTS MANAGEMENT

Your manufacturing uptime is key to us. By sourcing spares from ATS, you will lower your operating risk and equip your staff with the spares they need. Our spares recommendations are created by the ATS design, build, and service teams responsible for your system. The list is based on our knowledge and experience with automation systems and reliability engineering principles.

The recommended spare parts list considers:

Lead Time Requirements

if the item is a long lead item, such that failure would cause an extended period of downtime

Wear Considerations

if the item is a contact tool or wear component that will fail at some point in time

Duty Cycle

if the duty cycle of the component indicates that it will fail after a predictable level of use

Distribution

where the same part is used in multiple locations, a shared quantity has been included, and

Dependability

components that have a history of failure over time, (e.g. sensors)

Spare Parts Allotment of allocated funds held in reserve for spare parts replenishment as needed.

Benefits

- Single point of contact and competitive pricing for launch kits, replenishment inventories, and time-critical replacements

- Lower operational risk by purchasing original ATS parts that have been factory tested and inspected

- Reduce part acquisition time

- Ongoing spares replenishment can be purchased through ATS e-Commerce

Scope

- Can cover the required Critical, Contact and/or High Use Consumable Parts for optimal production performance

- Any parts required outside of the allotment will be quoted by ATS on an ad-hoc basis

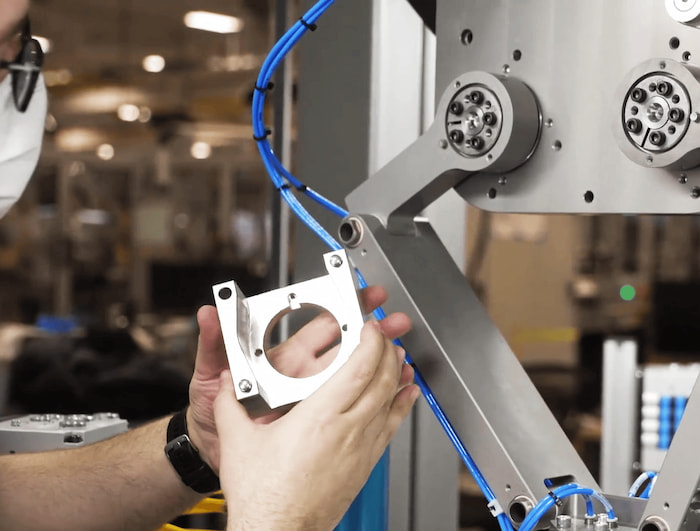

REFURBISHMENTS

In every product’s lifecycle there comes a time when improvements from VA/VE findings and new feature sets require a refurbishment of existing systems. ATS REM is there to support you with fleet management retrofit, providing the documentation, parts kit and resources to install retrofits to equipment.

FOCUS ON NEXT GENERATION

Like all products the end of life and limitations of retrofitting equipment forces us to consider a next generation design. With ATS REM as your trusted manufacturing partner, we are there supporting your next product release. With VA/VE engineering data, consolidated service data, and supply chain analysis, we are there collaborating with your design team to support the next generation product launch.

Resources

Let’s discuss your requirements

Contract Manufacturing meets surge and ongoing production needs. Our focus is on Repetitive Equipment Manufacturing for medium to high complexity equipment builds.