Ramp up the manufacturing process more quickly and get your products to market faster

PRODUCT LAUNCH EXPERTISE

In a highly competitive business such as systems integration and repeat build, REM leverages the scale and expertise of the ATS organization. Our ability to deliver our product or service is highly dependent on the efficiencies of our intra-departmental and divisional interactions. To minimize waste and improve communication speed and workflow we have implemented the following business systems:

PROGRAM MANAGEMENT

Design

SOURCING

MANUFACTURING

Services

1 PROGRAM MANAGEMENT

- Primary Point of Contact

- Robust Quality Planning Processes

- Risk Management Processes

2 Design

- Process design to minimize cost

- VA/VE

- New Product Capture

- Change Control Process

3 SOURCING

- Low cost sourcing strategy

- Global strategy to leverage buying power

- Local supply base optimized

4 MANUFACTURING

- Rigorous Quality Management

- Lean Methodology

- ERP System

- Methods and Controls

- Serialization & Traceability

5 Services

- Logistics

- Spare parts management

- Installation support

- Start-Up Support

- Training

- Refurbishment

VALUE ANALYSIS (VA) AND VALUE ENGINEERING (VE) FOCUS

VA/VE is the study of every element of cost in a part material, process and service to ensure that it fulfills its design function at the lowest possible total cost. VA/VE achieves the best balance between value and cost while not sacrificing quality, functionality or compliance to customer requirements.

VA/VE is a continuous cycle throughout the life of the program and consists of the following primary phases:

Assembly Evaluation

Determine compliance to specification

Screen & Quantification

- Identify major project components and their functions

- Assign cost to each component

Assess Feasibility

Develop and refine concept

Implementation

- Recommendation report

- Achieve consensus

- Create action plan

PROVEN SUPPLY CHAIN

ATS has the human resources, financial stability, and buying power to address supply chain challenges adequately and rapidly. ATS consistently monitors supply chain and procurement issues to ensure we align with the project build schedule. We have leading indicators that allow us to pivot quickly.

ATS has adopted Security of Supply (SoS) strategies to mitigate worldwide disruptions. The SoS team supports the Purchasing Departments by actively working with engineering and suppliers to put stocking strategies in place to ensure product availability.

SUPPLY CHAIN MANAGEMENT PORTAL | The Seven Driving Value Levers

Best Cost Country Sourcing

Buy where costs are inherently lower

Standardization / Redesign

Design cost out and/or standardize to increase part volumes

Systematic Supplier Management

Negotiate based on supplier competitive market

Demand Management

Buy economic quantities

Supplier Economics

Negotiate based on supplier cost

Bundling (Coordinated Buy)

Negotiate based on volume

Process Optimization

Eliminate waste for the supplier

SUPERIOR QUALITY

ATS is certified by SGS to the ISO 13485:2016 and ISO 9001:2015 standard that is inclusive of customer specific requirements.

ATS can configure a traceability module to meet customers’ requirements including development of a robust device history record (DHR) and retention of records. The retained records (traceability and DHRs) can be furnished in as little as a 24-hour period.

ATS’ objective is to produce products of high and consistent quality by the establishment, implementation, and maintenance of a defect preventing, cost effective, formal business system that satisfies the requirements of the ISO Standards and Customer Specific Requirements.

PROGRAM EXECUTION

Dedicated project and account leads are the customer advocates to ensure the voice of the customer (VOC) is maintained throughout the ATS organization. ATS gate process and controls are designed for high customer satisfaction and proven delivery performance.

Project Management Goal:

- Extensive Project Planning

- Precise Execution

- Effective Risk Management

- Customer Advocacy

- Thorough Communications

- Zero Red Programs, green to purple

Project Communication:

External:

- Bi-Weekly

- Project Scope

- Financial Status

- Key Accomplishments

- Upcoming Actions

- Stage Gate Project Milestones

- Current Project Issues

- Escalations (if required)

Internal:

- Weekly

- Budget Status

- Milestone Status

- Payment Status

- Open Issues

- Change Order Requests

- Deviations

- Recoveries

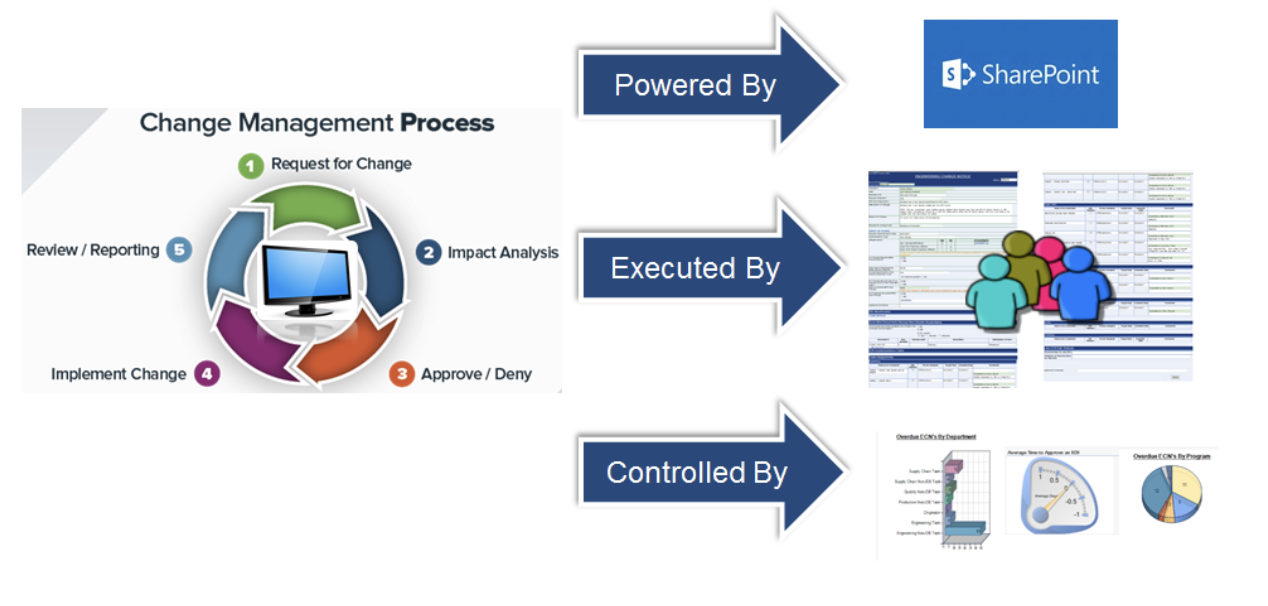

Change Management

Change is an inevitable event. ATS’ ability to manage these events dynamically and yet be responsive to your needs is imperative for the continued success of any project. Our implementation of SharePoint services allows us a clear and concise mechanism to request, review, and implement change effectively and accurately.

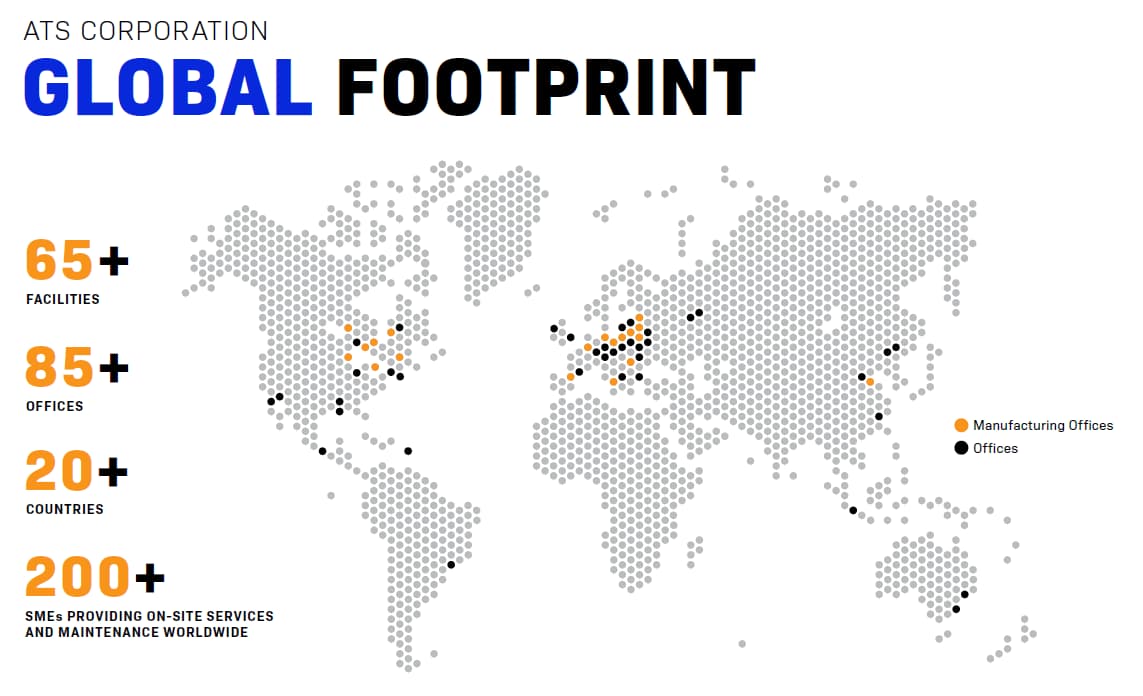

INFRASTRUCTURE TO SCALE PRODUCTION

With decades of experience to draw upon, ATS will leverage best practices to ensure objectives are met. A well-developed methodology, governed by ISO processes assures that large, multi-unit programs are kept on track.

ATS REM has extensive experience collaborating with customers to ensure we capture your technical scope and requirements.

65+ manufacturing facilities world-wide

>7,000 people

ATS Locations and Capability

Globally, ATS combined has over 1.3M square feet of space available to your program. Site selection will be based on varying factors to yield the highest potential for success.

Production methodologies within each facility include ERP-based material release and control, scheduling, Kanban techniques to control the assembly process, and a well-documented and executed process from order release through the shipping.

ABM starts with our Core Values

ATS REM’s pursuit to deliver value to our customers requires a culture of continuous improvement. Through the ATS Business Model (ABM), our quest for improvement, innovation, and excellence is rooted in our values of People, Process, Performance.

Resources

Let’s discuss your requirements

Contract Manufacturing meets surge and ongoing production needs. Our focus is on Repetitive Equipment Manufacturing for medium to high complexity equipment builds.