Information and details about ATS REM to help you better understand how we can work with you to achieve your manufacturing goals

Frequently Asked Questions

When we meet with prospective partners for the first time, we get questions. Here are some of the most common ones. Feel free to contact us if you have a specific situation that isn’t addressed here.

For an overview of REM services, click here to download our brochure.

What is ATS REM?

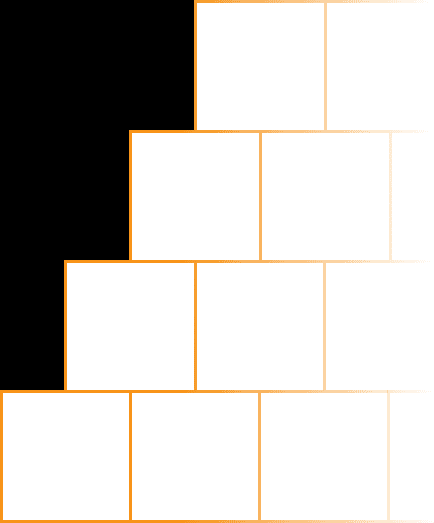

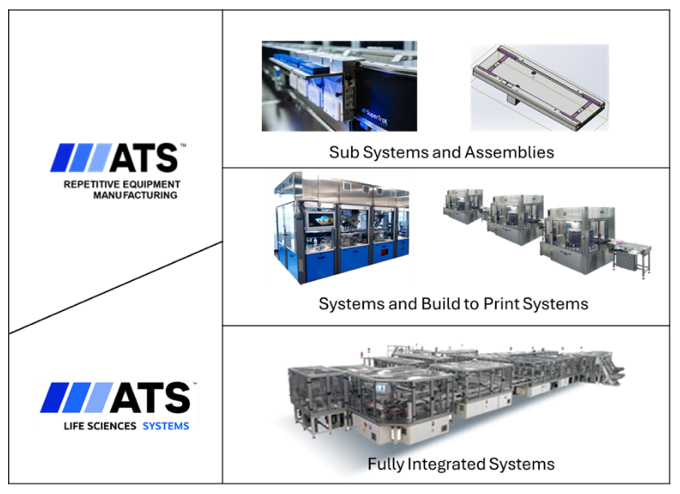

ATS REM is a division of ATS that provides contract manufacturing services and equipment assembly for a wide range of industries, focusing on mid to highly complex machinery. While large-scale automation partners primarily provide engineered to order solutions, REM is predominantly build to print. REM does not own the IP/design – it remains the customer’s own.

Where ATS REM delivers value is in the ability to:

- bring costs down

- employ cost-appropriate labour, primarily based in North America

- deliver on time, every time (99.8% OTD record)

- significantly enhance the design and performance of the machine through value analysis and value engineering (VA/VE)

- engage with customers close to their production facilities allowing for high visibility and accessibility throughout the partnership.

This is why at REM we say our process is:

ENGAGE | MAKE PERFECT | REPEAT

What types of projects best fit the REM model?

Here are some general guidelines for projects that align well with ATS REM:

- Volumes range from prototypes to 500+units

- Multi-year supply contracts

- Medium to high complexity

- 500 – 5,000 unique parts per BOM

- Unit values between $25k – $500k

How is REM used within ATS Corporation?

ATS REM serves as a strategic arm within ATS, focused on delivering consistent, high-quality, repetitive manufacturing solutions for customers across various industries, including ATS divisions.

For example, REM is the builder for SuperTrak CONVEYANCE™ and SYMPHONI™, an ATS digital assembly technology.

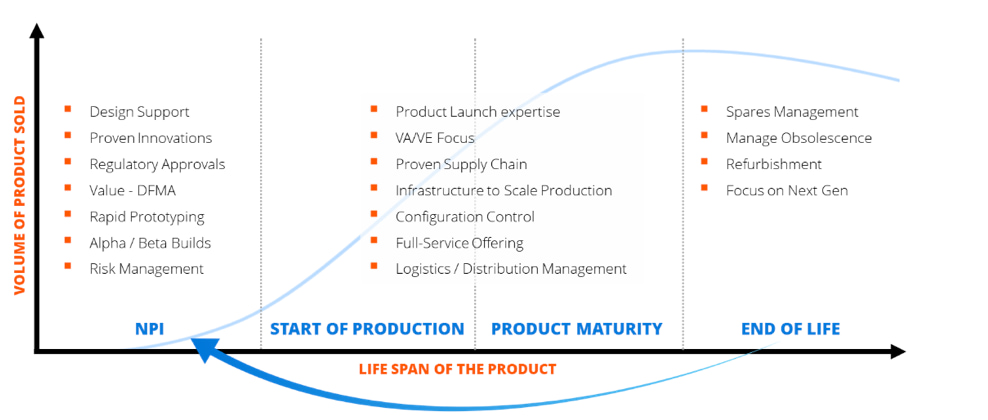

At what stage does ATS REM engage?

ATS REM can effectively engage at any point of the product life cycle, whether you’re in the design phase, in need of surge production support, or seeking a partner for ongoing production.

Why do companies outsource to ATS REM?

Outsourcing to ATS REM offers several key benefits:

- Focus on core competencies:

- Customers are often scientists or technology providers who want to focus on their expertise, leaving manufacturing to us

- Cost control:

- We help manage both direct and indirect costs, offering flexibility in scaling operations globally while providing cost-saving strategies such as tariff avoidance and supply chain management

- Supply continuity:

- ATS REM ensures regulatory compliance, business continuity, and spare parts and obsolescence management to keep your operations running smoothly

- Working capital optimization:

- We help reduce indirect costs, speed up time to market, and offer flexible manufacturing solutions

- We help reduce indirect costs, speed up time to market, and offer flexible manufacturing solutions

What is the difference between REM and contract manufacturing?

By definition, they are the same. While contract manufacturing covers a broad spectrum, REM specifically focuses on repetitive equipment manufacturing, with an emphasis on medium to high-complexity equipment builds.

Where REM is different is our base in North America, with local wage-appropriate labour, and the ability to deliver a clear idea of overall costs.

REM customers are very happy with delivery, very happy with quality, they know what to expect. REM facilities are accessible, customers can participate in workshops with us, making improvements, and seeing their project progress. Scorecards from our customers are exceptional.

How does ATS REM ensure quality control?

At ATS REM, we implement strict quality control measures at every production stage. Our processes are ISO 9001:2015 and ISO 13485 certified, and we comply with GMP standards to ensure that all equipment meets regulatory requirements and quality expectations.

We also adhere to the ATS Business Model (ABM) whereby continuous improvement and continuity of service applies to both our internal partners and external customers.

Can ATS REM support global projects?

Yes, ATS REM has a global presence and the ability to support international projects. Our global supply chain and manufacturing capabilities allow us to deliver solutions worldwide, ensuring local compliance and minimizing tariffs and logistical challenges.

How does ATS REM handle technological changes and updates?

We stay at the forefront of technological trends to ensure our customers’ equipment remains competitive. Our team provides ongoing support, including equipment upgrades, obsolescence management, and the integration of new technologies, ensuring that your systems evolve as needed.

How does ATS REM ensure scalability?

We design our solutions with scalability in mind, allowing you to start small and scale up as your business grows. Whether you need to increase production volumes or add complexity to your equipment, ATS REM provides flexible manufacturing solutions that adapt to your evolving needs.

Regulations & Certifications

REM provides manufacturing and operations services through our certified ISO 9001:2015 and REM: ISO 13485:2016 facilities, and FDA Registered CM for medical devices.

We can reduce cost, reduce lead time, and enhance reliability through quality and certifications.

- Functional safety design file

- SISTEMA report

- RoHS / Reach reporting

- Develop and conduct testing through the product lifecycle

- Manage, maintain and host audit of the manufacturing procedure

Virtual Tour

We’re opening the doors and inviting you in! Step inside our Cambridge, Ontario, location – global headquarters to ATS and one of our REM facilities. This 3D tour provides a bird’s eye view of our production floor; have a look and see what we can do:

When Experience Counts, and Time is Critical… Choose ATS

Curious to see more? We’d love to host you for a guided in-person tour so you can ask all the questions you need to about your assembly project. Ready to get started? Contact us today!