What’s Behind Our Repeat Manufacturing Success?

At ATS REM, we believe lasting success is built on true partnership. By aligning our manufacturing expertise with your product knowledge, we help you scale smarter.

Our proven process — Engage. Make Perfect. Repeat. — is designed to deliver consistent quality, reduce risk, and create long-term value. We rely on your expertise as much as you rely on ours, whether you’re launching a short-run assembly or scaling to full production.

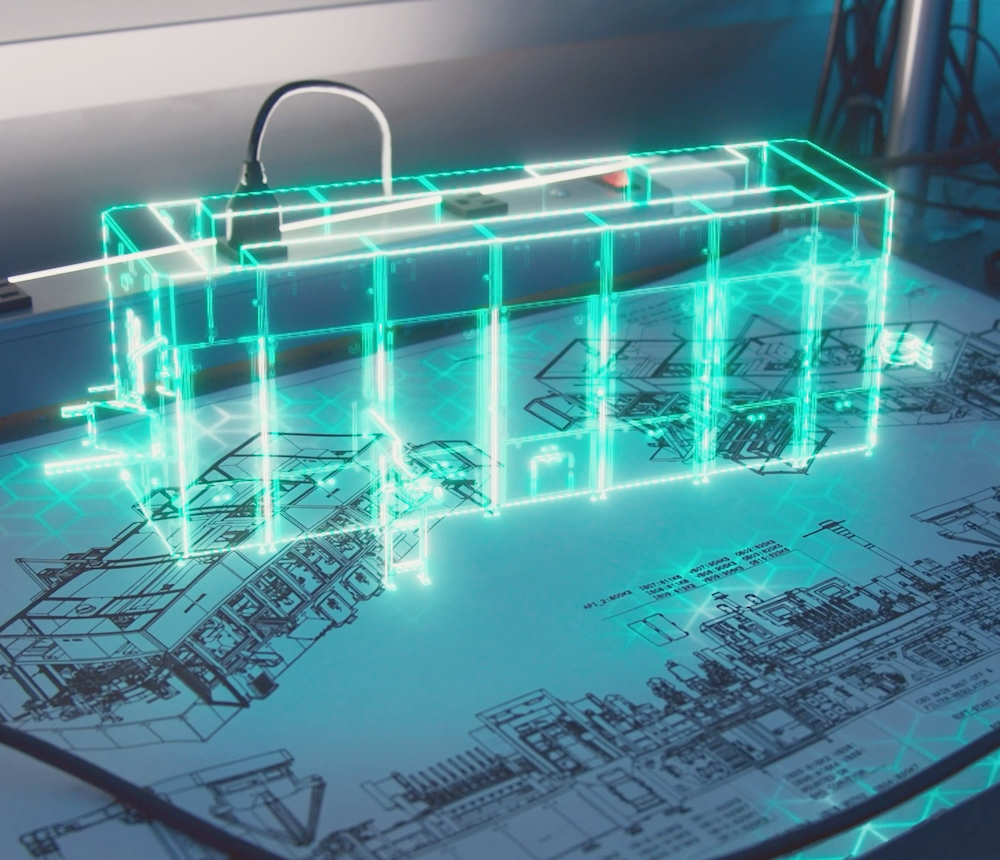

We engage.

We begin by aligning with your team to gain a comprehensive understanding of your product, goals, and challenges. This foundation sets the stage for smarter decisions and better builds.

Key Steps in the Process:

- Application & Systems Engineering – Define requirements and identify risks early

- Detailed Engineering – Execute design and mitigate technical challenges

- Assembly Integration – Build, debug, and test your first unit with precision

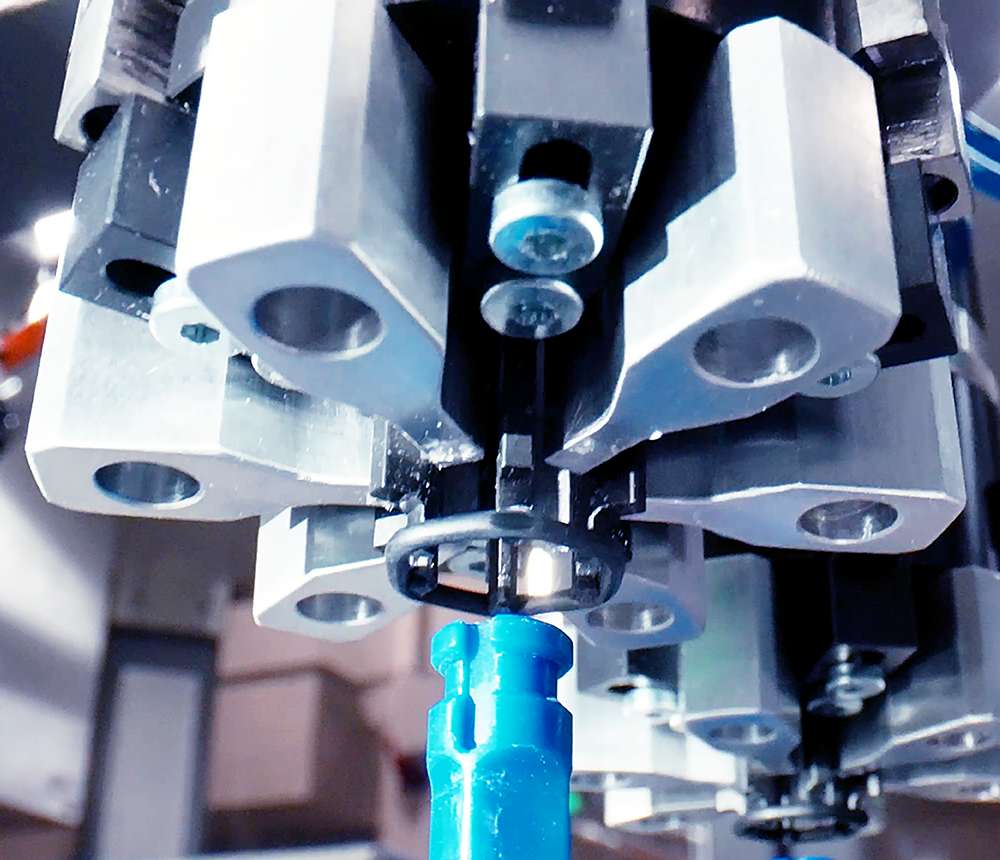

We make perfect.

We refine and optimize your equipment build for repeatability, cost efficiency, and quality — ensuring every unit meets your exacting standards.

Core Activities:

- Value Engineering – Reduce costs, streamline workflows, and enhance assembly instructions

- Assembly Ramp-Up – Introduce dedicated labor and set up lead production

- REM (Repetitive Equipment Manufacturing) – Standardize workflow and scale with confidence

We repeat.

We help you scale smarter — supporting continuous improvement, next-gen builds, and operational excellence.

Ongoing Support:

- Product Engineering – Refine your product and prepare for future generations

- Product Execution – Maintain consistency with dedicated labor

- Optimization – Improve supply chain, apply lean practices, and leverage the ATS Business Model (ABM)

Ready to outsource your equipment builds?

Reach out to our REM team to see how we can expand your production so you can focus on your business