REM is in the business of building multiple units over and over again, being able to utilize the engineering horsepower that ATS provides, with the ability to then improve design, find efficiencies throughout the process, so that we’re able to provide solutions at any scale.

When customers are dealing with REM, typically they’re looking for smaller islands of automation; we’re able to capture the small scale of those and duplicate those. So if you’re processing multiple islands of automation, we’re able to take that and then create a process in which we assemble in more of a structured manner. We are able to leverage cost-saving initiatives and design value effort and then execute based on your schedule or your capital expenditures to best suit your operational needs.

Adaptability is the point that we’re going for here. If we’re able to capture the process and then execute it over either a longer period of time or identify key time frames in which you need more deliveries or more units, we can build our process around that to help you meet your business goals.

When we receive the bill of materials, we work with our global supply chain partners to purchase all the materials that we need, get those on order so that we can start executing as quickly as possible, typically 10 or 12 weeks, depending on the size and scope of the project.

We have the ability to deliver as many or as few units as you need, depending on how your product is being produced, how your volumes are being used, how you see your business volumes coming together over the next year, two years, three years, five years, and we’re able to match that.

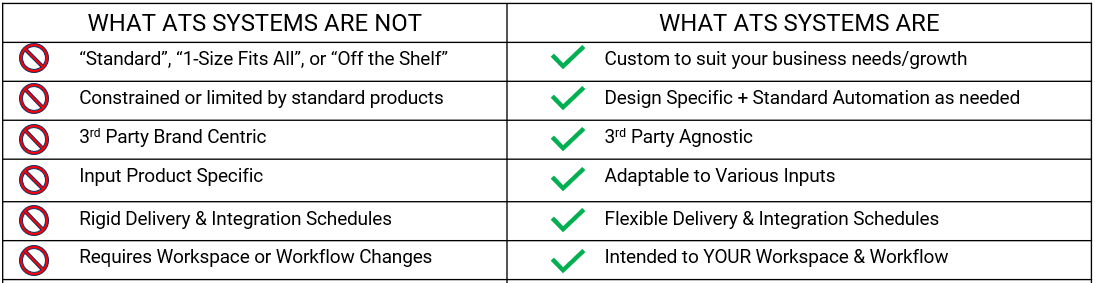

ATS offers custom automation solutions, but REM can fuse standard products along with those. For example, say your company for the past 35 years has been using a specific brand of robot or a system or a specific dispensing mechanism, we can take that as a standard component or work with your teams to engineer a different solution.

We can incorporate that all into our operation and then build you exactly what you’re looking for and what you need. So the advantage of having a custom solution is that you can have the same look, feel or schedule or any flexibility that you’re looking for in the future.

As you grow and drive your business, we’re able to make those changes with you, as opposed to a standard machine where vendors say this is our standard, this is what it has to do, what it has to be. We can build that right in or, as we’re a design house as well, we can make those changes early on or adapt them later in the future.

We’re talking about integration and being 100% machine agnostic; we’re able to take any programmer, programming logic controllers, robots dispensing units, anything you can imagine, we have experience and history working with all of those. So being able to tie those together, that’s where the integration piece comes into play.

For a smaller or medium sized organization that may be a market leader currently or just entering into the business, having the ability to grow and develop with those is where the REM team really starts to shine.

When you’re talking faster to market, ability to capitalize on opportunities that exist, those are times where REM comes into play. And as those business developments realize, we’re able to scale along with the growth that the customer may see.

People are the foundation of any business. Ensuring that human capital is a priority directly impacts on existing processes, as well as the performance of systems as noted by the growing trends in lab automation.

- Robots are particularly useful for routine and repetitive tasks allowing lab technicians to use their time on higher value tasks. For some tasks, collaborative robots (cobots) working with people can further enhance efficiency and standardization

- Delegating higher-risk tasks (dealing with biological matter or hazardous substances) to a robot mitigates the risk inherent with manual sample analysis and handling.

- As of 2023, the US alone was estimated to be short 3.4 million skilled technical workers

- In a 2023 CDC report, an average of 9% of all adults aged 18+ had reported an injury due to repetitive tasks in the previous three months. This average increased with worker age, up to 11.6% in those aged 55- 64.

Human capital is a huge factor to any business; the ability to best utilize that human capital is at the forefront of innovation and adaptation. Utilizing that human capital allows your company to either invest in new technologies, future technologies and growth opportunities, and let the machine and the automation system start to do the more manual, non-value add processes. For example, if you needed to take the cap off something every time you put it in a machine, why not put all of the parts into the machine and let the automation take the caps off?

So contract manufacturing, we’re building something for you; it’s exactly the same every time. Whereas with REM, what we’re looking at is a collaborative approach where we’re able to adapt to your business needs. We’re able to adapt to process changes or product changes all the way through the life cycle.

And we could get part of the way through a system, we could be 20 units into a 500-unit build, and we identify that we can make this more efficient for both the assembly and from the cost standpoint. If we’re able to work collaboratively with the customer to make those changes and realize those gains now that we’re able to produce those units faster or for a lower cost, then everyone wins.

The look and feel and operation is exactly the same, but those changes have an adaptive improvement to the existing design as we iterate through the process. That’s the difference; that’s value of ATS REM.