Summary

As laboratory workloads continue to grow, companies must streamline their workflows to minimize costs and speed up the process from sample receipt to patient results. Customers increasingly seek turnkey solutions that align with their specific workflow requirements rather than forcing them to adapt to generic systems or navigate complex vendor networks during expansion.

ATS REM responded to this need by reconfiguring a customer’s unique, proprietary process into an automated solution. This not only eased the strain on the physical space but also relieved the workforce burden, helping the lab handle more samples efficiently.

The Problem

Our client is a leading precision oncology company focused on helping conquer cancer globally using proprietary tests, vast data sets, and advanced analytics. After REM evaluated their proprietary workflow for processing samples, the constraints that would mitigate the success of achieving the desired outcome of increased capacity became apparent.

Common constraints with expanding laboratory capacity include:

- Cleanroom facility

- Manual processing and finding appropriate human capital

The Solution

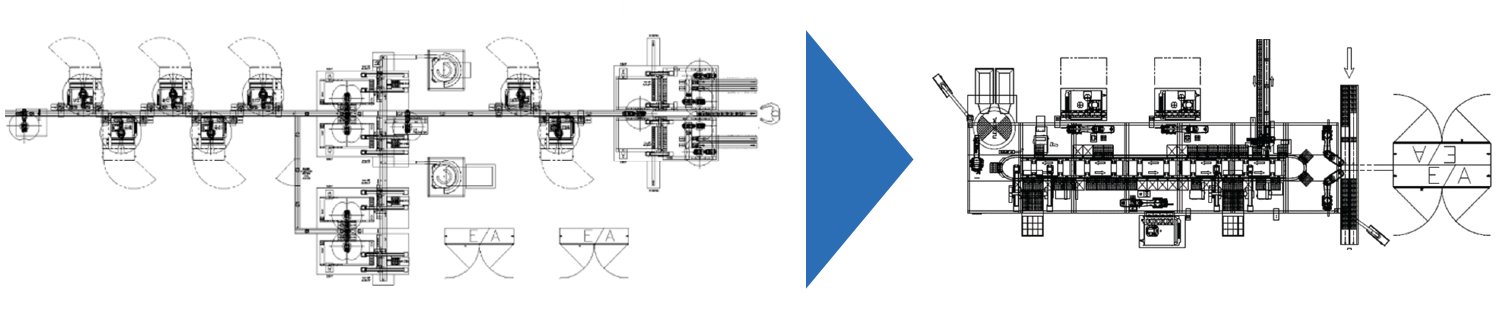

Leveraging our core technologies with SuperTrak CONVEYANCE™ for material handling from station to station, and our partner BioDot for liquid handling, ATS REM was able to reconfigure and reduce the existing footprint by over 75% while still respecting the customer’s proprietary process.

SuperTrak offers:

- Trusted, reliable technology

- Precision without mechanically docking

- High acceleration, low settling time with individual shuttle control

- Intuitive simulations to accurately plan line layout

Benefits compared to conventional systems:

- Lower cycle time cycle time

- Less footprint

- Typically +5% OEE (Overall Equipment Effectiveness)

- Increased availability with less maintenance

- Future flexibility to expand track length

BioDot offers:

- 30 years of experience supporting customers from R&D through high-volume manufacturing in the industrial, diagnostic, life science, and medical product markets

- Market leadership in automated small-volume liquid dispensing

Benefits compared to conventional systems:

- Flexibility with pipette tips to optimize aliquoting stations (<1mL to 5mL)

- High accuracy with syringe-pump resolution of ~400,000 vs traditional dispensing technologies with ~3,000 step resolution

The Results

With the new solution in place, our customer achieved the following:

- 75% reduction in footprint, optimizing their process in just 1/4 of the previous line layout

- 1/10 lab technicians required compared to their previous workflow

- +1,000 test tubes per hour, resulting in a 50% increase in capacity/throughput

REM, as a lab automation partner, leveraging the expertise of our ATS and LS Group partners, is the proven, reliable, efficient, and adaptable solution that can transform your business.