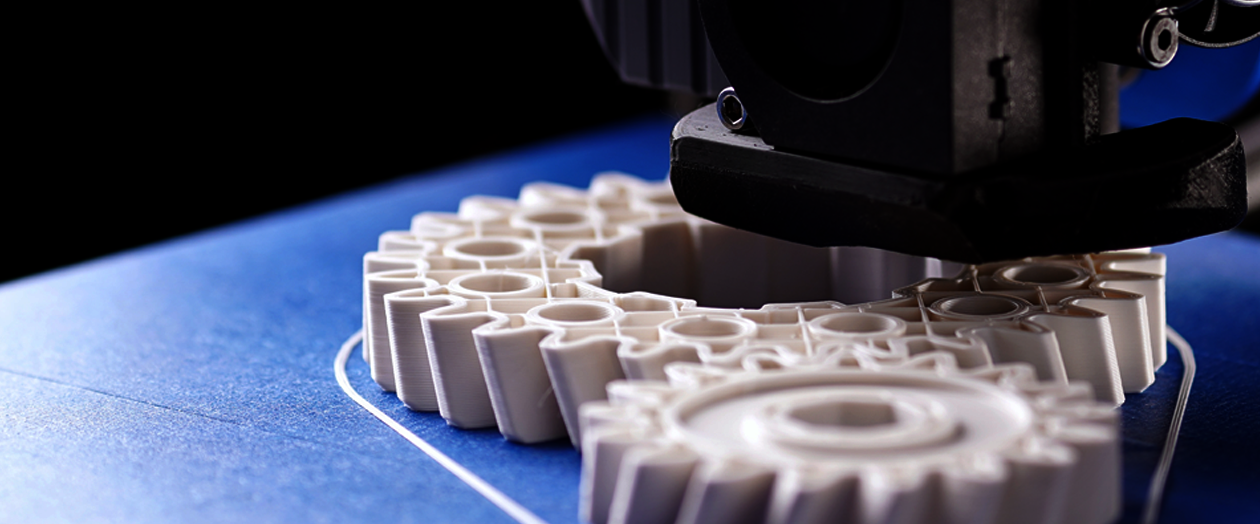

SCALABLE 3D PRINTER MANUFACTURING FOR AN ADDITIVE INNOVATION

ATS REM assembles high-quality, commercial 3D printers for the additive manufacturing industry by leveraging advanced technologies and streamlined production processes. We aim to empower businesses to innovate, reduce costs, and accelerate product development.

With a focus on scalability and adaptability, from prototyping to end-use production, ATS REM alleviates common concerns related to commercial 3D printer production, for industries including aerospace, automotive, and medical devices.

Turnkey Assembly Systems for High‑Volume 3D Printer Manufacturing

An innovative 3D printer OEM worked with ATS REM to implement a scalable assembly solution that reduces infrastructure strain, supports just‑in‑time delivery, and adapts quickly as production volumes grow.

THE RESULTS:

Scalable Production to Meet Manufacturing Demands

- Just-In-Time (JIT) delivery to support inconsistent demand

- Flexibility in managing change

Requirements for Additional Infrastructure and Resources

- Provided complete turnkey end-to-end systems in response to growing customer demands

Supply Chain Constraints

- Responsible domestic sourcing model

Quality Compliance

- Ensured consistency of product assembly throughout production by applying the principles of Value Analysis and Value Engineering (VA/VE)