With the growing demand for processing samples from diagnostic tests, labs need to find solutions to optimize their workflow to increase their capacity and deliver faster patient results. The obvious solution is to consider a transition from manual or semi-automated operation to full automation.

But when the solutions presented are ‘one size fits all’ and the transition requires new workflows, it’s easy to question where the value or return on investment (ROI) are.

Reduce cost while reducing lead time from sample receipt to patient results

ATS REM (Repetitive Equipment Manufacturing) has delivered over 1,000 lab automation systems for customers in hospitals, laboratories, and educational facilities. For over 25 years, customers seeking a turnkey solution that addresses their existing workflow needs (rather than forcing them to change their workflow to fit a standard solution) have trusted ATS REM as a proven partner in optimizing laboratory workflows.

ATS REM provides solutions directed by you, rather than selling equipment you have to adapt to.

How It Works

Derisk With Technology

ATS REM derisks automation projects by leveraging proven technologies addressing material handling, liquid handling, and data strategy. These technologies include:

- Linear track conveyance systems by SuperTrak CONVEYANCE™, pioneers of motion technology. ATS REM has been optimizing workflow solutions leveraging this technology for over 20 years.

- Microfluidic dispensing by BioDot, acquired by ATS in 2021. This liquid handling specialization enables dispensing of picoliter to nanoliter volumes at the highest possible speeds, allowing companies to do more with less and get to market faster.

- Sustainable OEE through Illuminate™ Manufacturing Intelligence software, providing an embedded data strategy to optimize and improve line performance.

Customer Engagement

A relationship-based approach means we have dedicated project and account leads who act as customer advocates, ensuring that the voice of the customer (VOC) is consistently maintained throughout the project. These projects are supported by an experienced, professional leadership team and hundreds of skilled experts.

ATS proven technologies and affiliated companies offer a one-stop-shop solution designed to improve your bottom line. With access to a vast network of industry experts, ATS ensures that projects are well-represented, taking full ownership to meet delivery deadlines and stay within budget.

STEP 1: ENGAGE

Apps/Systems Engineering

Requirements Definition Risk Identification

Detailed Engineering

Design Execution and Risk Mitigation

Assembly/Integration

1st Build Execution Debug and Test

STEP 2: MAKE PERFECT

Value Eng.

Cost Reduction Focus, Refine Workflow, Assy. Instructions

Assembly Ramp

Intro Dedicated Labour; Lean Production Setup

REM

(Repetitive Equipment Manufacturing) Ramp Dedicated Labour; Standardized Work

STEP 3: REPEAT

Production Engineering

Refinement, Next Gen, Further Value Engineering

Product Execution

Dedicated Labour

Optimization

Supply Chain Optimization, 5S, Lean, ABM

Culture of Innovation

Leveraging our ATS Business Model (ABM) and the Value Analysis / Value Engineering (VA/VE) process, ATS enhances customer outcomes. The breadth of core competencies and the diversity of our workforce create a strong foundation for developing competitive solutions tailored to any project. This approach empowers our personnel, increases customer satisfaction, and significantly improves overall project outcomes.

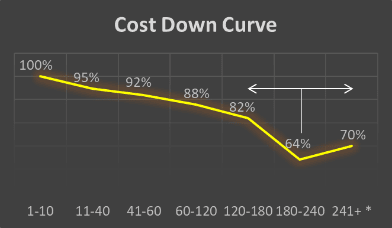

“ATS delivered on their commitment of a 35% cost reduction and 100% on-time delivery. We achieved our target cost point in approximately half the projected time, all while improving system uptime and first-pass yield.”

Superior Solutions

Transitioning from manual or semi-manual operations to full automation means customers can realize productivity gains in several ways:

- The ability to redeploy human capital for higher-value operations

- Confidence in meeting business commitments by being faster to market or ensuring continuous operations

A solution that integrates seamlessly with existing processes, equipment, and information management systems, and provides an intuitive interface for new equipment ensures that staff training and onboarding are not barriers to adoption or delays in realizing results.

“ATS REM delivered significant unit cost reductions while upgrading the product feature set, addressing BOM obsolescence, and improving aesthetics and ergonomics.”

—Medical Device Manufacturer

Benefits of Engaging with ATS REM for Lab Automation

ATS has the ability to review your end-to-end processes and offer solutions that provide significant improvements in various areas:

- Smaller footprint: ATS technologies enable a reduction of up to 4x in the physical space required for equipment.

- Improved Cycle Time: Processes are sped up by as much as 2x compared to conventional solutions.

- Reduced human capital dependency: Automation reduces reliance on manual labor for throughput.

- Risk mitigation: Reduces staff exposure to human samples and repetitive strain injuries.

- Improved chain of custody: Minimizes the risk of errors during sample handling.

- Enhanced performance: Uptime, availability, and reject rates are significantly improved.

Ultimately, this comes down to the balance of risk, reward, and ROI as a result of partnering with ATS REM. There are numerous success stories where selecting the right partner has provided businesses with a competitive edge and positively impacted their bottom line. ATS REM, a turnkey repetitive equipment manufacturer, has been building outsourced capital equipment for leading OEM brands for over 25 years.

Is it time to redesign or refresh your lab operations for improved functionality or prepare for the next generation? Consider partnering with an organization that offers expertise in design, engineering support, system integration, and automation.

ATS continues to lead the market with its comprehensive end-to-end enterprise solutions. Leveraging hundreds of subject matter experts to address complex challenges, ATS has consistently delivered customized, repeatable results without relying on an off-the-shelf approach.