The machine that builds the machine: ATS REM is a turnkey, end to end contract equipment manufacturer providing services from new product and prototype engineering support to FMMA and VA/VE engineering services, scalable manufacturing, as well as aftersales services and support. ‘The machine’ refers to our people, our processes, functioning in unison, forming a manufacturing production system which delivers equipment or machinery to meet customer goals.

Investing in lab automation is a significant step in achieving your corporate goals of improving your laboratory’s operations. Having a reliable collaborative lab automation partner is imperative to ensure your investment delivers results to your customers. When considering a reliable lab automation partner, you want a vendor who will be with you throughout your asset’s lifecycle supporting your changing needs as you expand your lab operations.

Our customers come to us wanting to automate workflow centers, to make them more efficient and increase throughput. They’re looking to automate the remaining manual processes throughout the lab operations to address their increasing demands. They’re looking to improve the quality of their data collection systems that would ensure they have error-free data collection.

Our customers are also looking to automate their processes and procedures and workflows to ensure that they have procedural adherence and compliance with their quality system. They want improved quality, improved safety within their lab operations. Automation will distance employees from hazardous materials and repetitive work.

Automation can improve your lab operations by:

- Reducing the risk of errors in the lab due to data transcription

- Eliminating the transportation and wait time between operations

- Introducing easy-to-use equipment requiring minimal operator intervention

- Lowering cost of ownership

The transition to automation is a big investment of time and resources so you want to consider an automation partner with experience not just in workflow automation, but with experience to integrate end-to-end solutions throughout your laboratory automation operations. REM has 25 years of experience delivering over 1000 lab automation systems globally to hospitals, laboratories, and educational institutions.

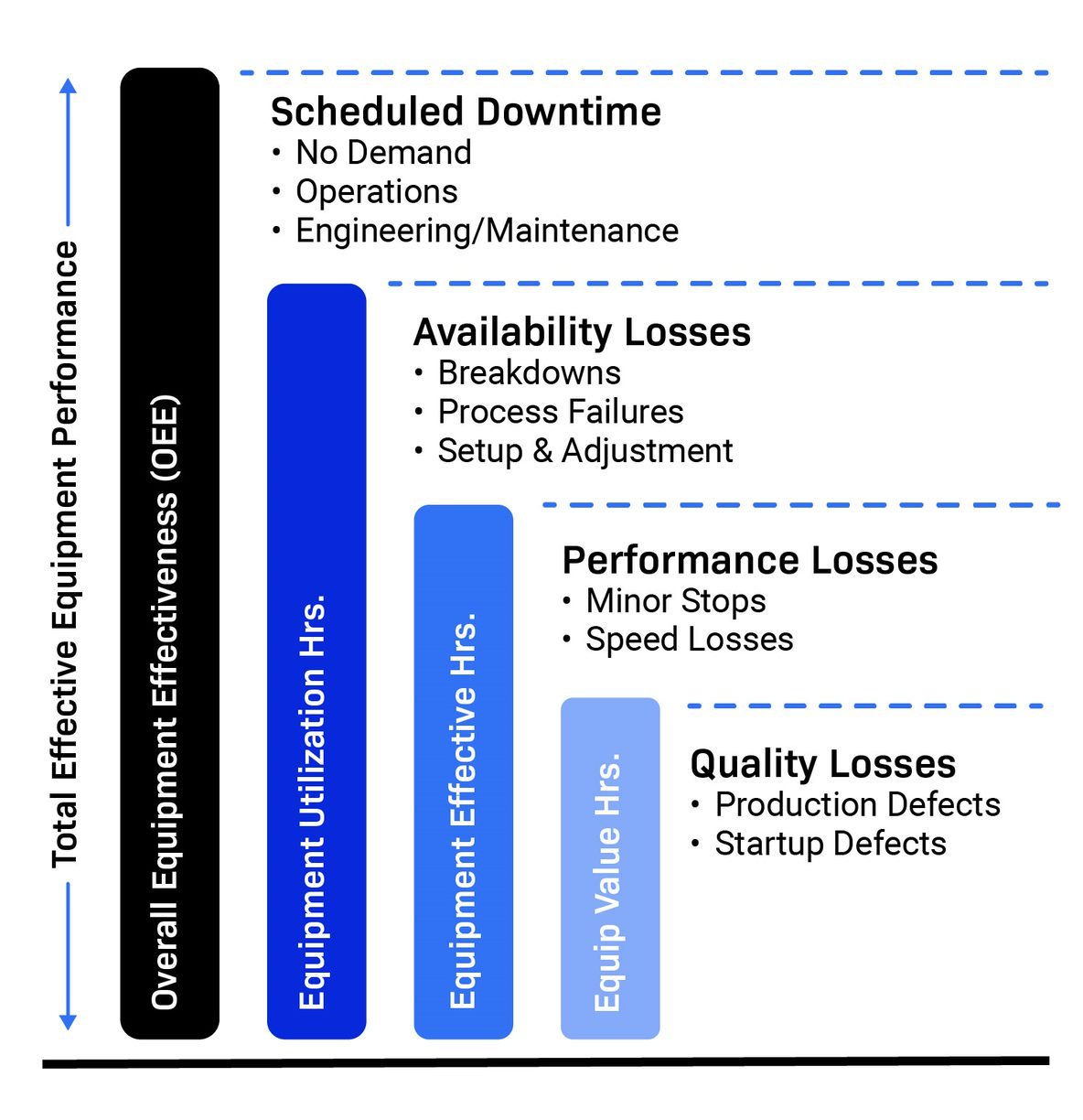

Choosing a reliable automation partner, you want to ensure that they have a proven project management system, which ensures that your project is delivered on time and on budget. You also want to consider a partner with a proven risk management program to help de-risk the project, as well as the equipment. You want a partner with a proven quality system that leverages years of proven best practices and a continuous improvement process that focuses on defect prevention as well as high yielding equipment performances.

When working with ATS REM, you can expect a partnership relationship that’s based on mutual success. We collaborate with our customers to ensure that we both understand the expectations, and we’re both focused on successfully achieving our goals.

Transforming your lab is a major step requiring considerable consideration to ensure success in optimizing your operations. You want a partner who is there with you through every step with the capabilities to deliver innovative solutions that incorporate your workflows efficiently. A reliable partner will:

- Ensure your laboratory operations needs are met

- Provide you with a first-time quality solution

- Deliver a solution on time

- Have processes that focus on defect prevention and yield high equipment performance

- Leverage best practices to develop strong processes and controls

- Be there throughout the asset lifecycle.

That’s exactly what you get when you choose ATS REM as your laboratory automation partner.